Assembling products on an assembly line is a process that has been around for many years. It is a way to speed up the process of putting together products and make them more efficient. But with constant innovation in many industries, this process can be made even more efficient with the help of technology. Many companies are now using various technologies to make their assembly lines more efficient.

Learn more about these technologies and how they can help your company improve its assembly line efficiency.

1. Robotics

One way to make an assembly line more efficient is to use robotics. Robotics can help with repetitive tasks requiring a high degree of accuracy. They can also work faster than human workers and don’t need breaks. This can help to speed up the assembly process and get products out the door more quickly.

Robots are also becoming more and more affordable as technology improves. Even small businesses can now afford to implement robotics on their assembly lines. They are a great way to improve efficiency and help save on labor costs in the long run.

2. 3D Printing

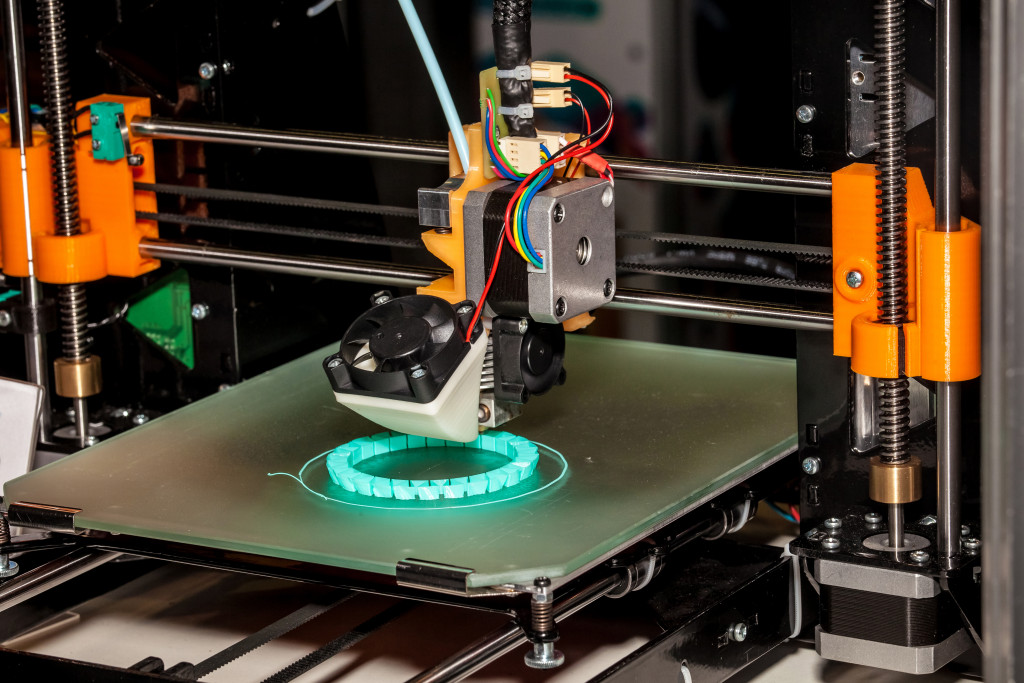

With the help of 3D printing, assembly lines can now create parts and products much faster than before. 3D printing technology has come a long way in recent years and can now create complex parts and products easily. This means that assembly lines can now create parts on-demand, which can help to speed up the overall production process.

While 3D printing is still relatively new, it is quickly becoming more popular in many industries. For example, the aerospace industry is now using 3D printing to create parts for aircraft. This helps reduce the aircraft’s overall weight and makes it more fuel-efficient.

3. Motion Control Systems

You must control every movement in an assembly line to keep the process running smoothly. This is where motion control systems come in. They help to automate the movement of parts and products on the assembly line. From moving parts to and from the conveyor belt to controlling the speed of the assembly process, these systems can help to make an assembly line more efficient.

They are also used in more complex applications such as welding and fabricating. This helps to improve the accuracy of these processes and reduces the need for human workers. Because some methods are labor intensive, automating them can help to save a lot of time and money.

4. Data Management Systems

Some assembly lines are now using data management systems to help with production. These systems help track each product’s progress as it moves through the assembly line. You can then use this information to improve the efficiency of the line.

For example, if a product takes too long to assemble, the data management system can help identify the bottleneck. The company can use this information to make changes to the assembly line to run more smoothly. They can also use it to track the progress of each product and ensure that it is being assembled correctly. This eliminates the need for manual inspection and can help improve the product’s overall quality.

5. Virtual Reality and Augmented Reality

Virtual reality (VR) and augmented reality (AR) are being used in more and more industries to improve efficiency. You can use these technologies to create virtual models of products and assembly lines. This helps engineers to design better assembly lines and identify potential problems.

You can also use VR and AR to train workers on how to use the assembly line. This can help reduce the need for on-the-job training and allow workers to be more productive. Especially on more complex assembly lines, VR and AR can be a great way to improve efficiency. When safety is also a concern, these technologies can help to create a safer environment for workers.

6. Collaborative Robots

Compared to standard robotics, collaborative robots (or cobots) are designed to work more closely with humans. They are often used in assembly lines where they can help with tasks such as packing products or adding components.

Cobots are becoming more popular because they are much easier to use than standard robotics. You can also use them in dangerous environments, such as welding applications. This helps to improve safety and can help to reduce the need for human workers in these applications.

You can use many different technologies to make an assembly line more efficient. From 3D printing to collaborative robots, these technologies can help to improve the efficiency of any assembly line. By using these technologies, companies can save time and money while improving their products’ quality.